Quality. Reassurance. Reliable.

Space Maching, Inc. has demonstrated a commitment to exceeding customer expectations through the creation and adherence to a quality system. Our quality system encompasses all aspects of the manufacturing process from receipt and confirmation of your order to production and delivery of your machined components.

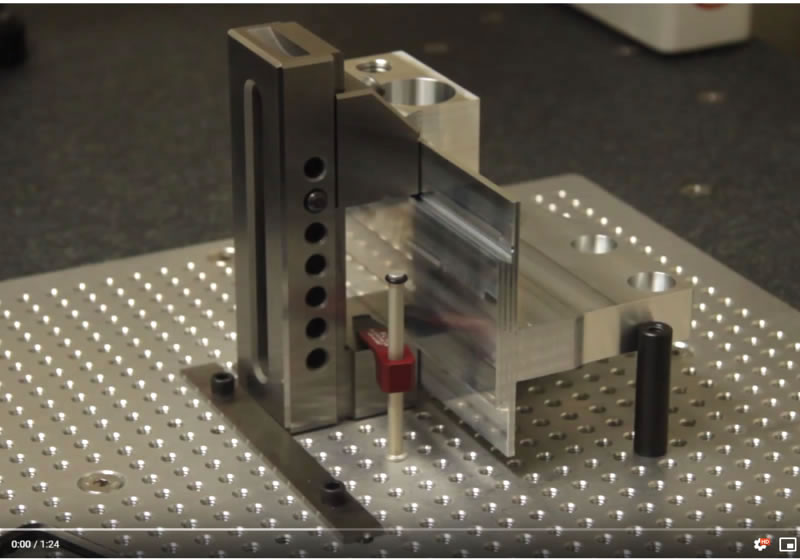

what we do

We are committed to total customer satisfaction and strive to meet or exceed customer requirements and expectations each and every time. We accomplish this by continuously improving our processes, products, services, communication and by monitoring our quality objectives.

Documentation

We provide documentation including first article, in process, and final inspection report as required.

INSPECTION EQUIPMENT:

- MITUTOYO CMM - TRAVEL 24 X 18 . BRIGHT M507

- 2019 MITUTOYO CRYSTA-APEX S574 CNC CMM PROBE HEAD RENISHAW PH10 PLUS WITH 6 PORT MCR20 AUTOMATIC TOOL RACK TRAVEL X 19.68" , Y 27.55" , Z 15.75"

- MITUTOYO : 0 - 1 DIGITAL MICRO

- MITUTOYO : 0 - 1 PIN-MICRO

- SPI : .80 -1.00 BORE - MICRO

- PRECISION MYER PIN SET: .011" - .750"

- DEL TRONICS PIN SET : 1/16 - 1/8 - 3/32- 3/16 - 1/4 - 5/16 - 3/8 AND INDIVIDUALS.

- MITUTOYO : 12" DIGITAL CALIPER

- MITUTOYO : 6" DIGITAL CALIPER